In the competitive world of fashion and branding, effective logo printing on clothes has emerged as a pivotal element for businesses aiming to establish a recognizable identity. Renowned expert in textile branding, Dr. Emily Chen, highlights, "A well-printed logo can turn a simple garment into a powerful marketing tool." This insight underscores the necessity for brands to prioritize quality and creativity in their logo printing strategies, ensuring their logos not only stand out but also resonate with their target audience.

As we approach 2025, the landscape of logo printing on clothes is evolving with advancements in technology and consumer preferences. Brands must adapt to these changes by incorporating innovative printing techniques that enhance durability, vibrancy, and brand visibility. Understanding the various methods available—such as screen printing, direct-to-garment printing, and heat transfer—will empower businesses to choose the best approach for their needs. By embracing these modern solutions, brands can elevate their logo printing efforts to new heights, ensuring lasting impressions on consumers and a stronger market presence.

Ultimately, the journey of logo printing on clothes is not just about pushing fabric through a machine; it's about telling a brand story that connects with consumers on a deeper level. With the right strategies and a commitment to excellence, brands can effectively leverage logo printing to bolster their identity and foster customer loyalty in an increasingly dynamic industry.

When it comes to printing logos on clothing, understanding the different printing techniques is crucial for establishing a strong brand presence. According to a recent industry report by Statista, the global market for custom apparel printing is expected to grow from approximately $3.64 billion in 2020 to $4.64 billion by 2025. This growth is driven by the increasing demand for personalized clothing, making it essential for brands to choose the right printing technique that best fits their needs.

Screen printing remains one of the most popular methods, especially for bulk orders, as it delivers vibrant colors and durability. Research indicates that screen printing is ideal for designs that require solid colors, as it can produce high-quality results even at lower costs for large batches. On the other hand, digital printing has gained traction for its versatility and capability to handle intricate designs and smaller runs. A report by Grand View Research highlights that digital textile printing is projected to witness a compound annual growth rate (CAGR) of 20.1% from 2021 to 2028. This technique allows brands to quickly adapt to changing trends without incurring significant overhead costs.

Each printing method has its unique advantages and disadvantages, which can significantly impact the final product and brand identity. As brands continue to explore these options, understanding the nuances of each technique will empower them to make informed choices that align with their brand strategy and audience preferences.

Choosing the right fabric is crucial for effective logo printing on clothes. Different materials interact with printing techniques in various ways, affecting both the vibrancy and durability of the logo. For example, 100% cotton is a popular choice due to its softness and breathability, making it ideal for screen printing. This natural fabric absorbs ink well, resulting in sharp and vivid designs that are comfortable to wear.

On the other hand, synthetic fabrics like polyester offer distinct advantages, particularly for dye-sublimation printing. This technique allows the dye to permeate the fabric, creating a long-lasting image that won’t fade or crack over time. However, it’s important to note that polyester can sometimes result in less vivid colors compared to cotton. Ultimately, understanding the characteristics of each fabric will help brands select the best option for their logo printing needs, ensuring a professional and visually appealing result.

When it comes to effectively printing logos on clothing, the placement of your logo plays a crucial role in ensuring it stands out and attracts attention. Optimal placement can transform a simple garment into a statement piece that speaks volumes about your brand. Consider the usual spots such as the chest area, sleeves, or even the back. Each location can create a different impact, with over-the-heart placements often seen as personal and approachable, while large back prints suggest boldness and style. An interesting design approach can also include asymmetric placements, which can catch the eye and make a more contemporary statement.

Another key factor is the size and color of the logo. It should be proportionate to the garment and contrast effectively against the fabric to enhance visibility. A logo that blends into the background may not leave a lasting impression, whereas one that pops can linger in the minds of potential customers. As the market becomes increasingly saturated with similar products, these design considerations can be the deciding factor that helps your brand remain memorable, ensuring your logo resonates well with your target audience and communicates your brand values succinctly.

When it comes to printing logos on clothing for your brand, choosing sustainable materials and methods is essential for both environmental impact and brand image. Opting for eco-friendly inks and fabrics not only reduces your carbon footprint but also appeals to the growing demographic of environmentally conscious consumers. Look for certification labels such as GOTS (Global Organic Textile Standard) or OEKO-TEX, which ensure that the materials meet stringent environmental and safety standards.

In addition to selecting the right fabrics, the printing method plays a critical role. Consider using water-based inks or dyes that are less harmful than traditional solvents. Techniques like direct-to-garment (DTG) printing or screen printing with eco-friendly inks can produce vibrant, long-lasting designs while maintaining a low environmental impact.

Finally, while the initial investment in sustainable printing methods may be higher, the long-term benefits including durability and customer loyalty can outweigh the costs. Emphasizing sustainability in your branding can help differentiate your products in a saturated market and foster a positive connection with your audience.

| Printing Method | Sustainability Rating | Cost per Unit | Minimum Order Quantity | Durability | Best Fabrics |

|---|---|---|---|---|---|

| Screen Printing | Medium | $2.00 | 50 | High | Cotton, Polyester |

| Direct-to-Garment (DTG) | High | $5.00 | 1 | Medium | Cotton, Blends |

| Heat Transfer | Medium | $3.00 | 10 | Medium | Polyester, Nylon |

| Sublimation | High | $4.00 | 25 | Very High | Polyester only |

| Vinyl Cutting | Medium | $2.50 | 5 | High | Cotton, Blends |

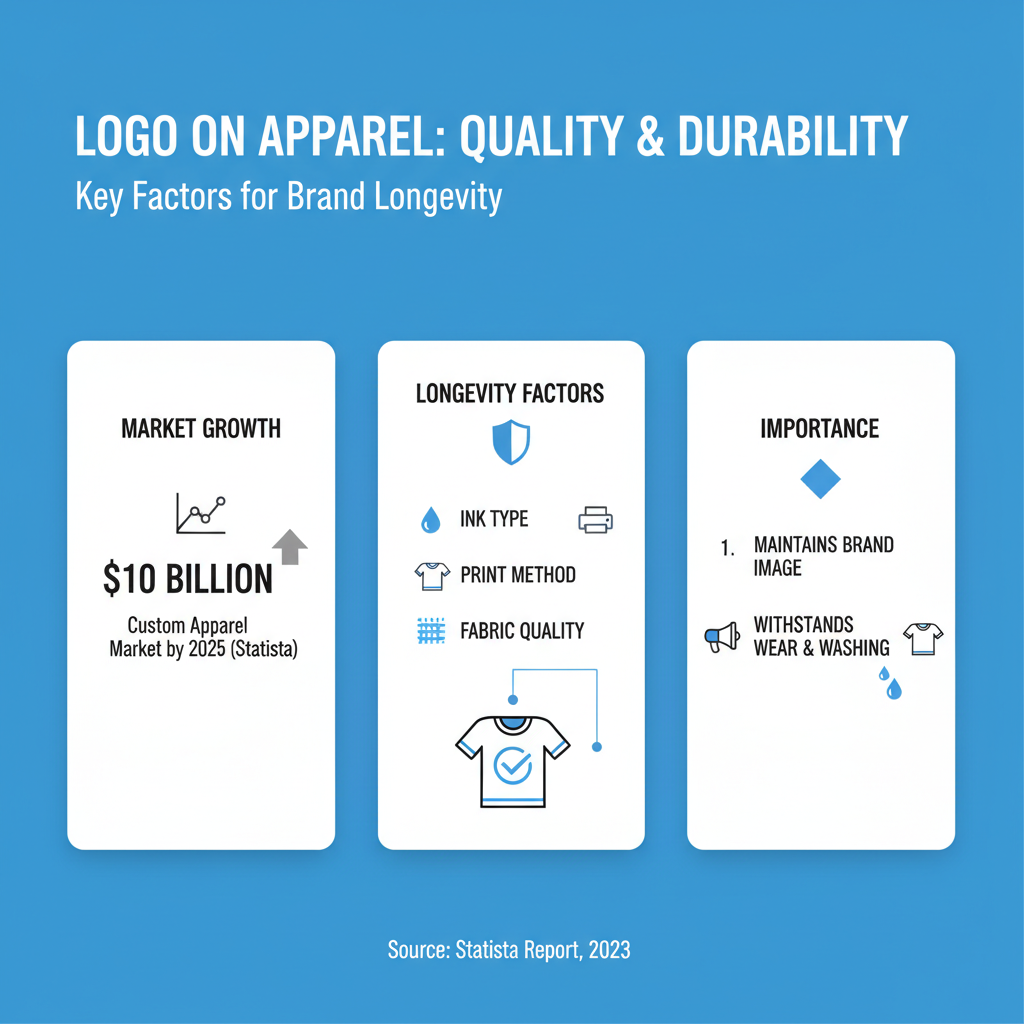

When it comes to printing logos on apparel, maintaining quality and durability is paramount for brand longevity. According to a recent report by Statista, the custom apparel market is expected to reach approximately $10 billion by 2025, underscoring the importance of high-quality prints that can withstand the rigors of wear and washing. The longevity of a printed logo is influenced by several factors, including the type of ink used, the printing method, and the quality of fabric.

Tips: Choose water-based inks over plastisol for a softer feel and better breathability, which contributes to the overall comfort of the garment. Additionally, consider using a direct-to-garment (DTG) printing method, as studies show it can produce more vibrant prints that last longer without fading, while allowing for intricate designs that screen printing may not achieve.

Another critical factor is the pre-treatment and curing processes. A report by the Custom Apparel Industry Association highlights that properly pre-treating fabric can enhance adhesion and prevent ink from fading after multiple washes. The curing process also solidifies the ink, making it more resistant to wear over time.

Tips: Ensure that garments are washed inside out in cold water to protect the printed logos and extend their lifespan. Regularly assess your printing techniques and materials to stay competitive in a growing market.